How we manufacture thermoplastic injection molded part for your project

1. Part Design >>

We design the plastic part or assembly in SolidWorks with regards to the manufacturability of injection moulding.

2. 3D printing >>

We produce a 3D printed model using FDM, SLA or Multijet Fusion method or by casting in silicon moulds 3D printing is not necesary step prior mould manufacturing.

3. Mould design >>

Based on our 25-years experience with injection moulding technology, we will design an injection mould.

4. Mould making >>

We produce the mould on our CNC machine tools or by electroerosion/wirecutting technology.

5. Prototyping >>

We produce the prototype from the required material on our injection moulding machines and send samples for approval.

6. Serial production

After approval of the samples, we will carry out serial production, including the provision of materials.

�

I) Injetion moulded parts out of thermoplastics

- We produce injection moulded parts from 0,001g to 450g, in cooperation more than 1kg, maximal processing temperature up to 430°C

- We work with all commonly available thermoplastics and thermoplastic composites - bulk (PP,PE,PS,ABS,), structural (PA, POM, +GF, +LGF, +CF, slip resistant), transparent (MABS, PC, PMMA), elastomers (TPE, SEBS, TPU), flame retardant, high-temperature high-tech materials (PPA, PPS)

- We also inject low volume series, including piece series. Our normal production series = 1.000 pieces to 10.000 pieces per order

- We deliver low volume 2K plastic parts - over-mouldings and insert-mouldings of metal or plastic parts

- We mark plastic parts using engraving fiber laser or using pad printing

- We proccess materials e.g. from výrobců EMS, Ticona, DuPont, Solvay, Styrolution, INEOS, Covestro, BASF, ExxonMobil, Sabic, Kraiburg, Trinseo, ENI, LANXESS, DSM, Poliblend LG +++

- and e.g. from these products: Grilamid, Grilon, Grivory, Technyl, Hostaform, Delrin, Crastin, Lexan, Altuglas, Terlux, Cycoloy, Terluran, Noryl, Eltex, Santoprene, Pharmalene, Desmopan, Durethan, Xytron, ForTii, Krasten +++

II) Injection moulds

- We specialize on precise CNC machined moulds made of aluminiun duralu or hardeded or non-hardened steel

- CNC machined moulds are 3 times to 10 times cheaper compared with hardened steel moulds

- In price we guarantee up to 50.000 shots or even more depending on complexity. We ordinarily achieve service life up to hunderds of thousands of shots

- Low price of mould + high service life + high quality of moldings = quick payback of investment without compromise in quality

- We devolepe and produce casting moulds for HOTMELT

- Made in Czech Republic

Injection molded parts from thermoplastics - selection of our products

- family company with low overhead costs and low communication noise

- 50 injection moulds manufactured annually, hundreds thousands of parts and processed tones of granulates

- 100% Czech company - all made in Czech Republic, on European machines and without subsidies

All under one roof

- Design of injection moulded parts

- Design of injection moulds

- Basic prototypes made by 3D printing or CNC machining

- Serial production of injected parts

- Additional services - marking of parts, assembly

Why should you manufacture with us

- Based on our 25-year experience we can approprietaly choose production technology - for super low series 3D printing (tenths of pieces), for low, medium and high series injection moulding of thermoplastics.

- smooth transition from prototyping and low-volume production series by 3D printing to mass production by injection moulding (in case the product is successful and there is a need to increase production)

- 25-years experience in injection moulding technology - hundreds of moulds and mouldings produced, millions of parts delivered

- we guarantee the final product = moulded part and delivery in the required quantity. The customer does not manage the communication between the designer, the tool room and the press shop.

- fast realization from demand to serial production - normally within 6 weeks, with EXPRESS service within a week.

- low prices of moulds - three to ten times cheaper than hardened steel moulds with the same quality of mouldings

- we normally guarantee 50 thousand strokes per mould, then we refurbish the moulds and extend its lifetime

- our moulds are customisable - ideal for development projects or low product life cycle

- we produce moulds with fast return on investment. At first sight, our moulds are cheap, but the opposite is true. Mouldings from CNC machined aluminium moulds forem produce same or even higher quality compared to those of hardened steel.

- industry branches: aerospace, machines, sports, hobby hunting weapons(airguns, airsoft), buildings, household, medicine, electrotechnics, electronics, protective equipment, IoT

- the ideal option for start-up projects thanks to low investment and our experience

- we are the gateway to the INFINITE WORLD OF THERMOPLASTICS

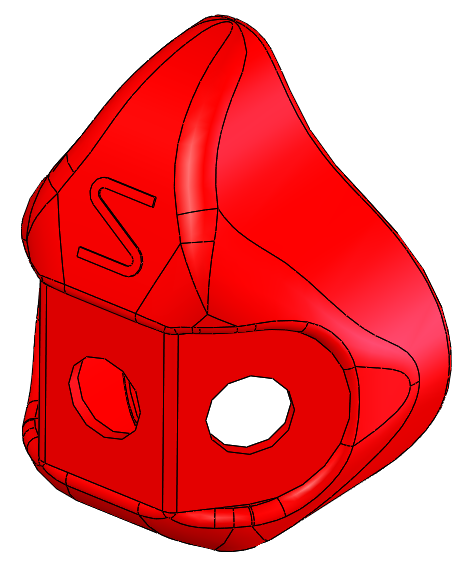

Half Mask X1 Advanced M - new half mask for fight with coronavirus

Due to the lack of protection instruments in fight with coronavirus COVID-19 we developed and created manufacturing capacity of half mask with removable filters. All done during six weeks in small Czech family company

Suchomel realizing projects in thermoplastics and machinery.

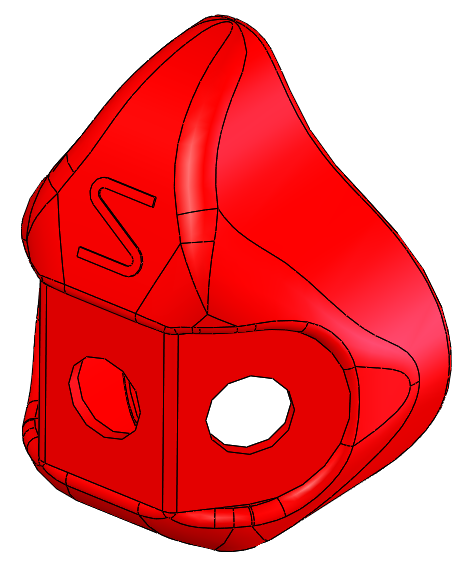

Half Maska Advantages

- SOFT FACEPIECE made of TPE guarantees high sealing potential and wearing comfort compared with surgical masks, respirators and 3D printed half masks with hard facepiece

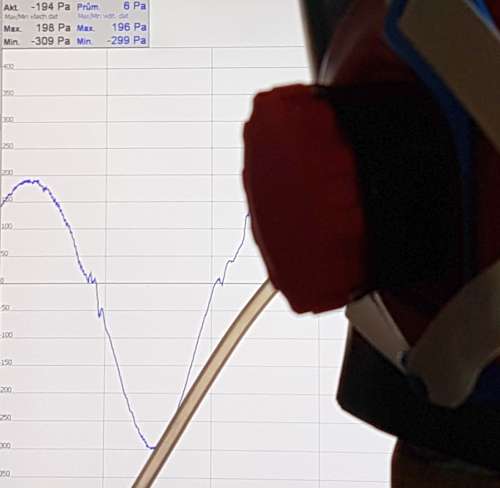

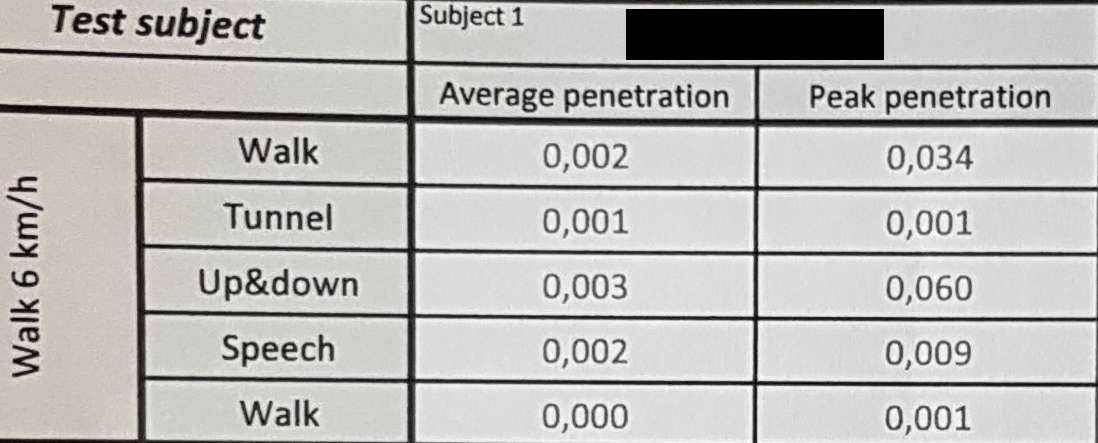

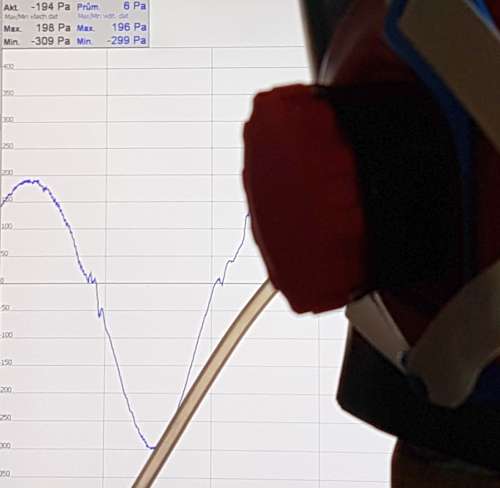

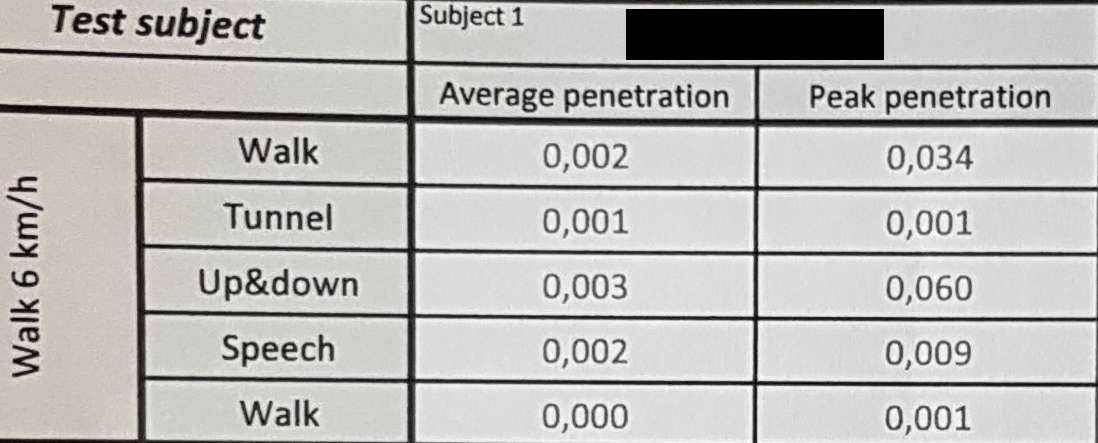

- INNOVATION of half masks sealing capability on face: penetration level with correctly mounted half mask is decreased by 3 orders bellow EN 140 requirements (measured penetration with P3R filter regarding 6.16 is 0,002%, norm requires 2%)

- the sealing force is applied to the TIP of the MASK, therefore the mask adapts better to different face shapes. The sealing force on the nose or chin can be fine-tuned by adjusting of the straps pre-tension.

- HIGH SEALING CAPABILITY compared with respirators and surgical masks

- proven EXHALATION VALVE from specialized manufacturer, silicone inhalation valves

- SURGICAL MASK PRINCIPLE principle applied on mask

- all parts are REPLACEABLE, which reduces costs in case of damage of particular part.

- the mask is REUSABLE; its repeated use reduces costs compared to disposable masks and respirators (the disadvantage is higher weight, size of the installation and the need for maintenance - washing or sterilization)

- SUSTAINABILITY: all parts (except valves and elastic straps) are made of thermoplastics that can be recycled. Cleaned parts can be reused in other production

- the mask is now available in MEDIUM SIZE M, which fits a wide range of faces. Child´s, S and L sizes are planned for the future

- to be available in different COLOURS (on pictures is unique combination for customers that what to differ)

- to be available in commen and MEDICAL QUALITY of materials

- designed and manufactured in the CZECH REPUBLIC: from European materials and Czech components

- intended for EN 140 certification

Filters

- the mask has an ORIGINAL proprietary bayonet for connecting filters of our own production (these are still under development)

- thanks to the adapter to RD40 1/7 "NATO thread, any STANDARDIZED dust or chemical FILTER can be used (it could be placed on the right or left side) = INDEPENDENCY on filters manufacturer (tenths of manufactures of standardized filters worldwide)

- possibility of manufacturing an adapter insert for filters from other producers

State of the Project

- long-term testing is in progress

- preparation for EN 140 certification running

- other virus filters are being developed

Supplies

- prototype pieces available in a week

- production capacity (without filters) is 2000 pcs per day (in case elastics, exhalation valves and materials are available)

- possibility to increase the production capacity by 2000 pcs per day in every two weeks (new molds and machine rentals)

Partners

Contact

Suchomel TECHNOLOGIE s.r.o. | Ing. Ondřej Suchomel/director | +420 777 688 199 |

ondra@suchomelplasty.cz